Humanity is facing an uphill battle when it comes to preserving our planet. According to the Intergovernmental Panel on Climate Change, in order to avert some of the worst effects of climate change we need to stop global temperatures from rising 1.5 degrees Celsius above pre-industrial levels.

One tool that could help is green hydrogen.

Green hydrogen is made through a process known as electrolysis. Here, a device known as an electrolyzer splits a compound into its constituent elements using an electric current. Most often this compound is water, which is divided into hydrogen and oxygen. If the electricity used comes from renewable sources, like wind and solar, the subsequent hydrogen is known as “green.”

According to the International Energy Agency, less than 0.1% of hydrogen today is produced through water electrolysis, but that could soon change.

“We actually see a complete dive down of hydrogen production cost,” says Haim Israel, global strategist and head of thematic investing at BofA Securities. He said that electrolyzer prices are down 50% since five years ago, and renewable energy costs have fallen 50%-60%. “We believe both of them will go down another 60 to 70% before the end of the decade,” he said.

The majority of hydrogen today is used in industry, including oil refining, ammonia production, methanol production and steel production. But, recent advancements in green hydrogen technology are making it much more appealing for a number of different industries.

In transportation, hydrogen fuel can act as a direct replacement for gas and diesel. Unlike electric vehicles, which can take around 30 minutes to charge with the fastest charging stations, hydrogen fuel cell cars can be ready to go in minutes. But fuel cells, which convert hydrogen fuel to useable energy for cars, are still expensive. And the hydrogen station infrastructure needed to refuel hydrogen fuel cell cars is still widely underdeveloped. Still, experts think hydrogen can be especially effective when it comes to long-haul trucking, and other sectors such as freight shipping and long-haul air travel, where using heavy batteries would be inefficient.

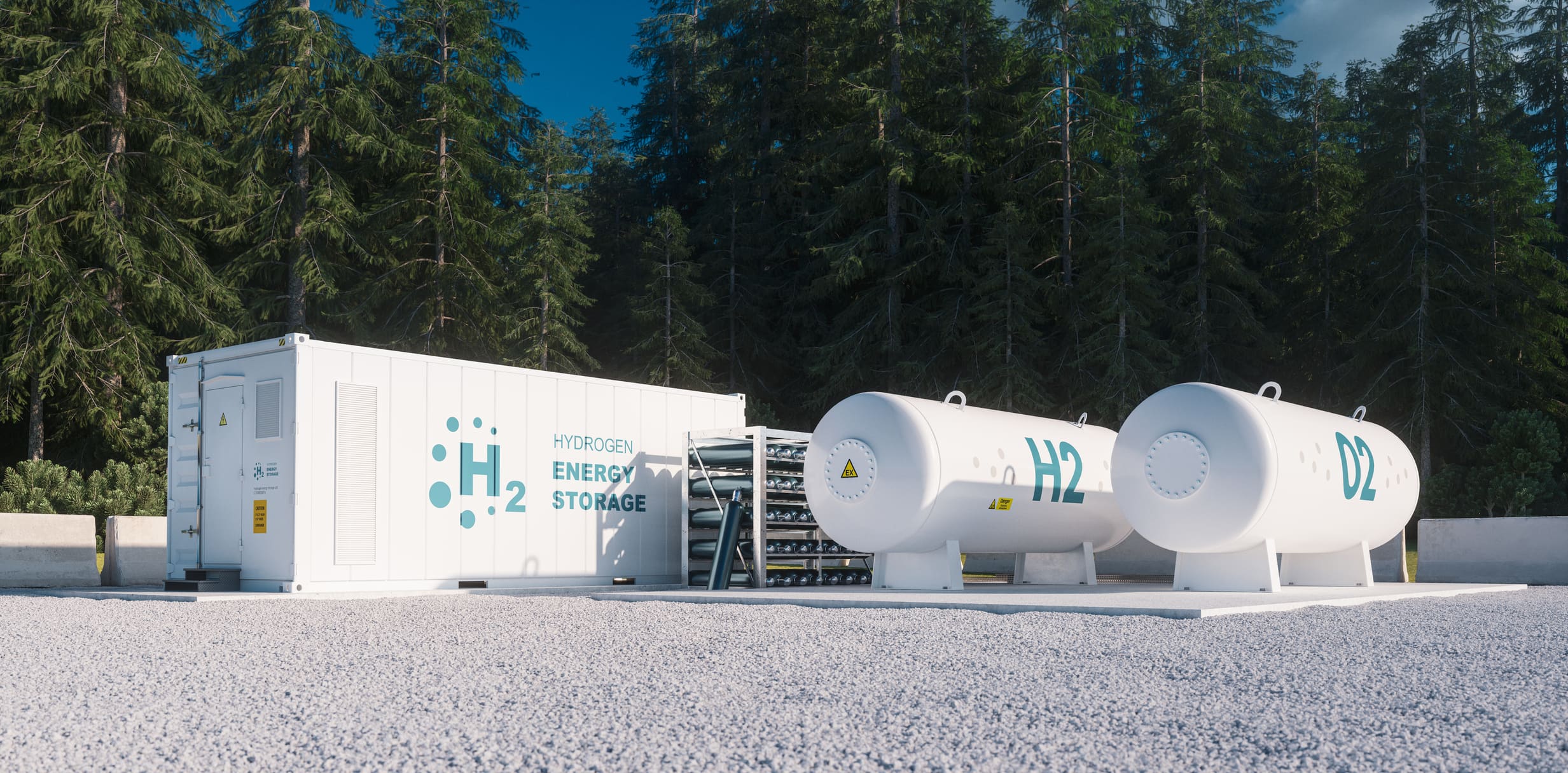

Another potential use for hydrogen is storing renewable energy that would otherwise be wasted. Mitsubishi Power and fuel storage company Magnum Development are working on a project in Utah to build a storage facility for 1,000 megawatts of clean power, partly by keeping hydrogen in salt caverns. Scheduled to be operational by 2025, the Advanced Clean Energy Storage project would be the largest clean energy storage system in the world.

“We’re going to build a very large electrolysis system that will be able to convert renewable power into hydrogen,” said Paul Browning, president and CEO of Mitsubishi Power Americas. “We’re going to store that hydrogen in that salt dome for long periods of time so that it can be used when the grid needs the electricity instead of when it’s produced.”

Hydrogen could also be used to heat our homes and to decarbonize a range of sectors that have proved hard to clean up in the past. This includes the chemical, iron and steel industries.

In fact, analysts at BofA Securities think that by 2050, clean hydrogen could account for an estimated 22% of our energy needs, up from just 4% of the energy that hydrogen supplies today. But this would require massive amounts of additional renewable electricity generation.

BloombergNEF estimates that generating enough green hydrogen to meet a quarter of our energy needs would take more electricity than the world generates today from all sources combined, and an investment of $11 trillion in production, storage and transportation infrastructure.

“In 50 years, I believe that hydrogen is going to be a very integral part of our life,” Israel said. “If we are serious about decarbonization, we just have no choice but to have hydrogen in scale.”